The Art of Precision Designing Injection Molding Tools for Quality

Understanding the Fundamentals of Injection Molding Tooling

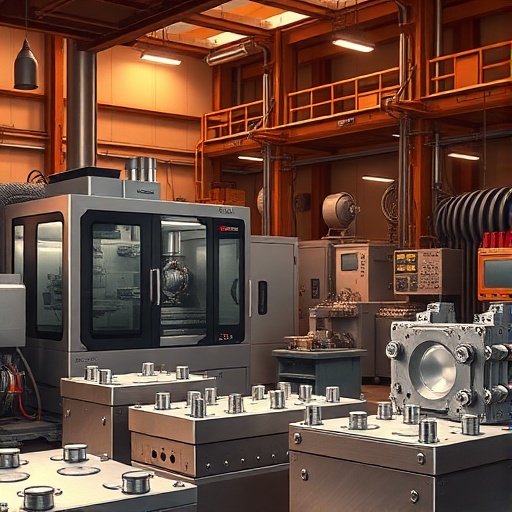

The Heart of Injection Molding: Tools and Molds

Injection molding tooling forms the core of any successful plastic injection molding operation, serving as the essential framework that shapes molten plastic into precise components. Engineers design these tools to withstand immense pressure during the injection process, where thermoplastic resins flow into the mold cavity under high force. The mold itself acts as the heart of the system, dictating the final product's geometry, surface finish, and overall quality. Without robust injection mold tools, manufacturers face inconsistencies in wall thickness, sink marks, and ejector pin failures that compromise production runs. Tool construction demands a deep understanding of how the injection molding machine interacts with the mold, ensuring even distribution of molten plastic to avoid defects. In high-volume scenarios, these tools must endure thousands of cycles, balancing cost with durability. Injection molds typically consist of two halves—a core and a cavity—that clamp together, allowing the plastic to cool and solidify before ejection. This setup enables mass production of intricate parts, from automotive components to medical devices. Designers prioritize the mold's alignment and sealing to prevent flash or leaks, which could ruin batches. By focusing on tool injection molding principles, companies achieve repeatable results, reducing waste and enhancing efficiency in plastic molding workflows. The evolution of injection mold design has incorporated advanced simulations to predict flow patterns, minimizing trial-and-error during setup. Ultimately, mastering the heart of injection molding—its tools and molds—drives innovation in manufacturing, enabling faster cycles and superior part integrity across industries.

Material Selection: Steel, Alloys, and Their Role in Tooling

Selecting the right materials elevates injection molding tooling from basic functionality to high-performance reliability, with steel and alloys standing out for their strength and heat resistance. Tool steels, like P20 or H13, dominate due to their ability to handle repeated exposure to molten plastic temperatures exceeding 300 degrees Celsius. Alloy steel variants enhance hardness, reducing wear from abrasive resins and extending tool life in demanding applications. Aluminum, while lighter and cheaper, suits prototypes or low-volume runs, offering quick machining and cooling for shorter cycle times. Cost plays a pivotal role; steel molds command higher upfront investments but deliver long-term savings through durability in high-volume production. Engineers consider the resin type—whether thermoplastic or specialized blends—when choosing alloys, as certain steels resist corrosion from additives in plastic injection molded parts. The role of these materials extends to maintaining tight tolerances under pressure, preventing deformation that could lead to molding defects. In metal injection molding, robust alloys ensure precision for powdered metal feeds, while for standard plastic injection molding, surface finish on the tool directly imprints on the part. Balancing machinability with endurance, manufacturers often blend steels with chromium or molybdenum for superior performance. This strategic selection not only optimizes injection tooling design but also supports sustainable practices by minimizing replacements. As industries push for lighter, stronger components, advanced alloys continue to redefine material roles in injection molds, fostering efficiency and quality in every cycle.

Designing for Precision: Key Considerations

Geometry and Tolerances: Ensuring Accuracy in Molding

Precision in injection mold design starts with meticulous geometry and tolerances, which guarantee that every plastic injection molded part meets exact specifications. Engineers map out the mold cavity to mirror the desired shape, accounting for shrinkage rates unique to each thermoplastic resin—typically 0.5% to 2%—to avoid distortions. Tolerances, often held to ±0.001 inches, demand exact control over wall thicknesses to prevent weak spots or uneven cooling. The geometry influences molten plastic flow, where sharp corners or thin sections can trap air, causing voids or sink marks. In high-precision applications like electronics housings, designers incorporate draft angles of 1-2 degrees for smooth ejection, reducing stress on ejector pins. Tooling for injection molding requires CAD software to simulate pressure distribution, identifying potential hotspots before manufacturing. This approach cuts costs by minimizing prototypes and rework. Surface finish specifications, from polished to textured, transfer directly to the part, enhancing aesthetics and functionality. For complex geometries, modular designs allow adjustments without full redesigns, boosting flexibility in molding systems. Tolerances also extend to alignment between core and cavity, ensuring consistent gate placement for uniform filling. By prioritizing these elements, manufacturers achieve superior accuracy, supporting industries from aerospace to consumer goods where even minor deviations spell failure. Injection mold tooling variations, such as family molds for multiple parts, further refine geometry to optimize production efficiency.

The Importance of Gate and Sprue Design

Gate and sprue design anchors the efficiency of injection molding, controlling how molten plastic enters the mold cavity to produce flawless parts. The gate, a small opening at the mold's entry point, directs flow and influences weld lines, where streams recombine—poor design leads to visible seams or weak structural points. Engineers select gate types like edge, fan, or pinpoint based on part complexity and resin viscosity, ensuring even pressure distribution to avoid short shots. The sprue, the primary channel funneling material from the injection molding machine's nozzle, must taper smoothly to prevent turbulence that causes flow marks or incomplete fills. In hot runner systems, insulated manifolds maintain molten plastic temperature, eliminating cold sprues and reducing waste from solidified runners. This design choice lowers cycle times and material costs, especially in high-volume injection tooling. For overmolding techniques, precise gate placement prevents flash between layers, preserving multilayer integrity. Surface finish around the gate affects shear rates, impacting molecular orientation in the final plastic injection molded product. Designers use flow analysis to optimize sprue diameter, typically 4-8mm, balancing fill speed with cooling uniformity. Addressing these elements head-on minimizes defects like gate blush, where color inconsistencies mar appearance. Ultimately, thoughtful gate and sprue configurations elevate injection mold tools, enabling consistent quality and scalability in diverse molding injection applications.

Addressing Complexity: Advanced Mold Designs

Advanced mold designs tackle the growing complexity of injection molding tooling, enabling production of intricate parts that traditional methods can't handle. Engineers employ multi-cavity molds to produce dozens of identical components simultaneously, slashing per-unit costs in high-volume scenarios. Unscrewing mechanisms and lifters address undercuts and threads, rotating or sliding cores to release parts without damage. For high-complexity items like medical implants, hybrid designs combine steel cores with aluminum exteriors for rapid prototyping while maintaining precision under pressure. Injection mold design software simulates resin flow in complex geometries, predicting issues like air traps or warpage before tooling fabrication. Manifold systems distribute heat evenly across the mold, crucial for thin-walled parts where cooling variations cause sink marks. The rise of conformal cooling channels, machined via additive processes, follows the part's contours to accelerate cycles by up to 50%. These innovations suit thermoplastic overmolding, layering materials for enhanced properties like grip or insulation. Cost considerations guide complexity; while advanced designs increase upfront engineering expenses, they yield long-term gains in productivity. Ejector pins and side actions must integrate seamlessly to avoid scarring the surface finish. By embracing such sophistication, manufacturers push boundaries in plastic molding, delivering custom solutions for automotive, electronics, and beyond, where complexity meets uncompromising quality.

Manufacturing Processes and Techniques

Machining Techniques for Precision Tools

Machining techniques define the precision of injection molding tools, transforming raw stock into molds capable of withstanding rigorous production demands. CNC milling dominates, carving intricate geometries from tool steel blocks with tolerances under 0.0005 inches, ensuring accurate mold cavities for molten plastic flow. Electrical discharge machining (EDM) excels at hard materials, creating fine details like ejector pin holes without mechanical stress. Wire EDM cuts complex shapes, ideal for prototypes or repairs in injection mold tooling. High-speed machining reduces cycle times, using specialized cutters to achieve mirror-like surface finishes that imprint directly on parts. Engineers sequence operations—roughing for bulk removal, then finishing for accuracy—to minimize tool wear and maintain geometry integrity. For aluminum molds in low-volume runs, softer techniques like conventional milling suffice, cutting costs without sacrificing speed. Heat treating follows machining to harden steels, enhancing resistance to pressure and abrasion from abrasive resins. Quality checks via CMM (coordinate measuring machines) verify dimensions, preventing downstream defects. These techniques adapt to injection tooling design variations, from single-cavity to stack molds, supporting diverse molding styles. As automation integrates, 5-axis machines enable undercuts in one setup, streamlining tool manufacturing. Precision machining not only builds durable injection molds but also optimizes overall manufacturing efficiency, delivering tools that power consistent, high-quality plastic injection molding.

Utilizing Tool Steels and Aluminum in Injection Molds

Tool steels and aluminum serve distinct yet complementary roles in injection molds, guiding manufacturers toward optimal choices based on production needs and budgets. Tool steels, such as 420 stainless or NAK80, provide exceptional wear resistance for high-volume injection molding, enduring millions of cycles under intense pressure from molten plastic. Their thermal conductivity ensures uniform cooling, reducing warpage in complex designs. Pre-hardened varieties streamline machining, balancing cost with performance for medium runs. Aluminum alloys, like 7075, shine in rapid prototyping due to their lightweight nature and excellent machinability, allowing quick iterations in injection mold design. Though less durable than steels, aluminum molds cut lead times by 50% and lower initial costs, ideal for low-volume or short-run plastic molding. Coatings like PVD enhance aluminum's surface finish, extending life against corrosive resins. In hybrid applications, steel inserts in aluminum bases combine durability with speed, suiting overmolding techniques. Selection hinges on factors like part size, cycle volume, and resin type—abrasive fillers demand tougher tool steels. Engineering teams evaluate trade-offs: steels offer longevity but higher machining expenses, while aluminum accelerates market entry. Both materials support tight tolerances, with steels preferred for precision engineering in automotive parts. Utilizing these options strategically advances injection tooling, fostering innovation and reliability in molding systems.

Fasteners and Assembly: Building Durable Tools

Fasteners and assembly techniques solidify the durability of injection molding tools, ensuring molds withstand clamping forces exceeding 100 tons without misalignment. High-strength bolts and dowel pins anchor components, maintaining precise alignment between cavity and core during high-pressure injections. Engineers select alloy steel fasteners for their tensile strength, resisting shear from ejector forces and thermal expansion. Assembly follows a modular approach, allowing easy maintenance—interchangeable inserts facilitate tweaks for different resins or designs. Torque specifications, often 50-200 ft-lbs, prevent loosening over cycles, with lock washers adding security. In stack molds, specialized clamps distribute load evenly, supporting multi-level production without distortion. Surface treatments like zinc plating combat corrosion from plastic vapors, extending fastener life. For complex assemblies, hydraulic cylinders integrate for automated actions, enhancing safety and precision in tool construction. Cost-effective choices include socket head caps for accessibility, while custom pins ensure repeatability in geometry. Quality assembly minimizes play, crucial for avoiding flash or pin marks in final parts. Training assemblers on best practices reduces errors, aligning with ISO 9001 standards. These elements transform individual machined pieces into cohesive injection mold tools, ready for relentless operation. By prioritizing robust fasteners and meticulous assembly, manufacturers build tools that deliver unwavering performance in plastic injection molding environments.

Quality Control and Benchmarking in Injection Molding

Implementing ISO 9001 Quality Systems

Implementing ISO 9001 quality systems revolutionizes injection molding by establishing standardized processes that ensure consistent tool performance and part excellence. Certification demands documented procedures for design, machining, and assembly, from initial injection mold design reviews to final inspections. Auditors verify traceability, tracking materials like tool steels through the supply chain to prevent subpar alloys from entering production. In tooling for injection molding, this means rigorous checks on tolerances and surface finish, using statistical process control to monitor variations. Training programs equip teams to identify risks, such as improper gate design leading to defects, fostering a culture of continuous improvement. ISO 9001 integrates with benchmarking, comparing cycle times and defect rates against industry leaders to drive efficiencies. For high-volume runs, it enforces preventive maintenance schedules, extending mold life and reducing downtime costs. Documentation aids in root-cause analysis for issues like sink marks, ensuring swift resolutions. Suppliers must comply, guaranteeing quality resins and fasteners. This holistic approach not only meets regulatory demands in sectors like medical plastic molding but also boosts customer trust through certified reliability. Companies adopting ISO 9001 report up to 30% productivity gains, as systematic quality controls minimize waste in injection molding operations. Ultimately, these systems embed precision into every facet of tool manufacturing and use.

Common Molding Defects and Their Solutions

Common molding defects plague injection molding if not addressed, but targeted solutions rooted in tool design and process tweaks restore quality. Sink marks, caused by uneven cooling in thick walls, resolve through optimized gate placement and conformal cooling channels that equalize temperatures. Short shots, where molten plastic fails to fill the cavity, stem from insufficient pressure or clogged sprues—solutions include adjusting injection speeds or cleaning manifolds. Weld lines weaken parts when flows merge poorly; redesigning runner systems or raising melt temperatures merges streams seamlessly. Flash occurs from excessive clamp force or worn molds, fixed by recalibrating the injection molding machine and resurfacing tools. Burn marks from trapped gases demand venting upgrades in the mold cavity to release air safely. Ejector pin marks minimize with precise alignment and polished surfaces. For warpage, balancing cooling times across the tool prevents differential shrinkage. Material inconsistencies, like splay from moisture, require pre-drying resins. In overmolding, delamination solves via compatible thermoplastics and controlled interface pressures. Benchmarking defect rates guides improvements, with statistical tools tracking occurrences per thousand parts. Proactive designs, such as rounded corners to reduce stress, preempt issues. By systematically diagnosing and remedying these defects, manufacturers enhance surface finish and structural integrity, ensuring plastic injection molded products meet stringent standards without escalating costs.

Measuring Productivity and Efficiency in Molding Operations

Measuring productivity and efficiency in molding operations relies on key metrics that illuminate injection molding tooling's impact on throughput. Cycle time, from injection to ejection, serves as a primary indicator—optimized tools shave seconds per part, amplifying output in high-volume scenarios. Overall equipment effectiveness (OEE) combines availability, performance, and quality rates, benchmarking against targets like 85% to spotlight bottlenecks such as slow cooling in aluminum molds. Scrap rates track defect prevalence, with low percentages signaling robust designs that minimize waste from sink marks or flash. Throughput volume, parts per hour, evaluates tool scalability, where multi-cavity injection molds excel. Energy consumption metrics assess efficiency, as efficient manifolds reduce power draw during molten plastic heating. Downtime logging pinpoints maintenance needs, ensuring steels endure without frequent interventions. Software dashboards integrate data from injection molding machines, providing real-time insights for adjustments like pressure tuning. Cost per part calculations factor tooling investments against production gains, justifying advanced features. Benchmarking compares these against peers, adopting best practices in injection tooling design for gains. Employee KPIs, including setup times, foster skilled handling of complex assemblies. By rigorously measuring these elements, operations achieve leaner workflows, higher yields, and sustained competitiveness in plastic molding landscapes.

Future Trends in Injection Molding Tooling

Reshoring and Its Impact on Tool Manufacturing

Reshoring reshapes tool manufacturing by bringing injection molding operations back to home soils, driven by supply chain vulnerabilities and rising overseas costs. Domestic production accelerates prototyping, slashing lead times from months to weeks with local machining expertise. U.S. and European firms invest in advanced facilities, prioritizing tool steels and alloys sourced nearby to cut tariffs and logistics expenses. This shift boosts employment in engineering and boosts innovation in injection mold design, tailoring tools for regional resin supplies. Reshoring enhances quality control, aligning with ISO 9001 for traceable processes that reduce defects like warpage. High-volume capabilities grow with automated CNC and 3D-printed molds, enabling rapid scaling. Cost savings emerge from eliminated shipping risks, though initial setups demand capital for state-of-the-art injection tooling. Sustainability drives adoption, as shorter supply chains lower carbon footprints in plastic injection molding. Collaborations with local universities spur R&D in hybrid materials, blending aluminum for speed with steels for durability. Government incentives, like tax credits, fuel this trend, revitalizing manufacturing hubs. Impact extends to customization, where reshored operations offer flexible molding styles for niche markets. Overall, reshoring fortifies tool manufacturing resilience, ensuring agile responses to market demands while upholding precision and efficiency.

Innovations in Plastic Resins and Overmolding Techniques

Innovations in plastic resins and overmolding techniques propel injection molding tooling into new realms of functionality and sustainability. Bio-based thermoplastics, derived from renewable sources, replace petroleum resins, demanding tools with enhanced corrosion resistance to handle their unique flow properties. Recyclable blends reduce environmental impact, with molds designed for multi-material compatibility to avoid contamination. Overmolding advances layer soft-touch grips over rigid substrates, using precise manifold systems to control interface bonding under pressure. Two-shot molding integrates colors or materials in one tool, minimizing assembly steps and costs. Nanofillers in resins boost strength, requiring tighter tolerances in cavity geometry to capture fine details. Smart resins with embedded sensors enable self-monitoring parts, influencing ejector and gate designs for delicate handling. Cooling innovations, like water-assisted channels, pair with these resins to prevent sink marks in thick sections. Tooling variations adapt, incorporating hot runners for low-viscosity bio-plastics to maintain flow. Engineering focuses on surface finishes that enhance adhesion in overmolding, ensuring durable laminates. Cost efficiencies arise from longer cycles with premium resins, offset by premium part values. These developments expand applications in electronics and automotive, where overmolding delivers ergonomic, lightweight solutions. By embracing resin innovations, injection tooling evolves, meeting demands for eco-friendly, high-performance plastic injection molded products.

Exploring Variations in Tooling for Different Molding Styles

Exploring variations in tooling unlocks versatility across molding styles, adapting injection molding tools to specialized processes beyond standard thermoplastic injection. Gas-assist molding employs hollow cores to inject gas, forming lightweight parts—tools feature dedicated ports and pressure controls to shape internal voids without defects. Insert molding integrates metal components like pins or threads, requiring precise cavity alignments to secure inserts during molten plastic fill. Micro-molding for tiny precision parts demands ultra-fine machining, with tolerances under 10 microns and specialized ejectors to handle delicate geometries. Stack molds stack multiple levels for doubled output, using synchronized fasteners for stability under high volumes. Family molds produce varied parts in one cycle, optimizing runner designs for balanced flow. For low-pressure molding, like encapsulating electronics, softer aluminum tools suffice, reducing stress on sensitive inserts. Hybrid tooling combines traditional machining with 3D printing for rapid prototypes, testing variations before steel commitment. These styles influence material choices—alloy steels for abrasive metal injection molding, versus standard for plastic. Gate and sprue configurations vary, from submarine gates in aesthetics-focused styles to large sprues for high-fill rates. Benchmarking productivity across styles guides selection, ensuring efficiency in diverse applications. As molding injection evolves, tooling variations empower manufacturers to innovate, from medical devices to consumer goods, with tailored precision and cost-effectiveness.

See Also

- Understanding Tolerances in Injection Molding Tooling for Perfect Fit

- Mitigating Molding Defects The Key to Successful Injection Tooling

- A Deep Dive into Reshoring and Its Impact on Injection Molding Tooling

- From Design to Production How Injection Mold Tools Shape Innovation

- Innovative Strategies for Boosting Productivity in Injection Molding Operations