Unlocking the Secrets of Weld Neck Flanges in Power Plant Engineering

Understanding Weld Neck Flanges in Power Plant Engineering

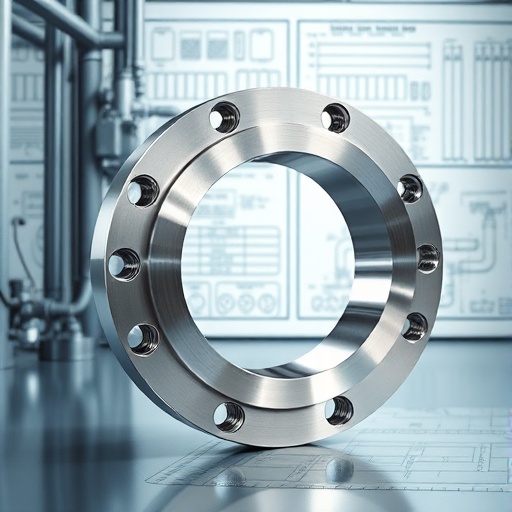

What are Weld Neck Flanges?

Weld neck flanges stand out as essential components in piping systems, featuring a long tapered hub that seamlessly integrates with pipes through welding. Engineers design these flanges to connect pipes, valves, and other equipment, ensuring a robust joint that withstands extreme conditions. In power plants, weld neck flanges handle high-pressure steam lines and coolant systems, where their tapered neck gradually merges the flange with the pipe, reducing stress concentrations and preventing leaks. Manufacturers produce weld neck flanges in various sizes, from small diameters for auxiliary lines to large ones for main turbine piping. The welding neck flange design enhances flow efficiency by minimizing turbulence at the connection point. Unlike slip-on or socket weld flanges, weld neck flanges offer superior strength, making them ideal for critical applications. Piping specialists often specify weld neck pipe flanges when dealing with high-velocity fluids or gases. In construction projects, teams install these flanges to link pipes, hoses, and nipples securely. The flange weld neck configuration allows for full penetration welds, which bolsters the overall integrity of the assembly. Power plant engineers rely on weld neck flanges to maintain operational safety, as their structure supports rigorous testing protocols. Overall, weld neck flanges represent a pinnacle of engineering precision, combining form and function to support complex infrastructure.

Applications in Power Plants and Beyond

Power plants deploy weld neck flanges extensively in boiler systems, where they connect high-temperature pipes carrying superheated steam. These flanges endure the rigors of thermal cycling and pressure fluctuations inherent in electricity generation. Beyond power plants, industries like oil and gas utilize weld neck flanges in pipeline networks to transport crude oil and natural gas under immense pressures. In petrochemical facilities, weld neck flanges link reactors and distillation columns, ensuring containment of volatile chemicals. Manufacturing sectors adopt these flanges for heavy-duty machinery setups, while waterworks systems use them in large-diameter pipes for municipal water distribution. Food and beverage processing plants select weld neck stainless steel flanges for hygienic piping that handles liquids without contamination risks. Heating systems in commercial buildings incorporate weld neck flanges to join heating pipes and radiators efficiently. Construction firms integrate flanged connections during infrastructure builds, valuing the durability of welded neck flanges. Engineers in the oil and gas industry often pair weld neck flanges with valves and nipples to create leak-proof assemblies. The versatility of neck flanges extends to offshore platforms, where corrosion resistance proves vital. Power plant applications highlight their role in turbine inlet piping, while broader uses in engineering underscore their adaptability across sectors. Weld neck flanges thus form the backbone of reliable fluid transport in diverse environments.

Key Specifications and Standards (ANSI, ASTM)

ANSI and ASTM standards govern the production and use of weld neck flanges, ensuring uniformity and reliability in engineering applications. ANSI B16.5 outlines dimensions, pressure ratings, and tolerances for pipe flanges up to 24 inches, specifying how weld neck flanges must align with mating components. ASTM specifications, such as A105 for carbon steel forgings, detail material properties to guarantee performance under stress. Engineers reference these standards when selecting weld neck ANSI flanges for power plants, where compliance prevents catastrophic failures. Specifications include bolt hole patterns, facing types like raised face or ring-type joint, and pressure classes from 150 to 2500 pounds. In manufacturing, adherence to ASTM A182 for stainless steel ensures corrosion resistance in harsh settings. NPT threads sometimes complement weld neck flanges in transitional fittings, though full welding remains preferred for high-pressure zones. Standards also cover testing requirements, mandating hydrostatic tests to verify pressure integrity. Power plant designers incorporate these specs to match flanges with existing pipe and valve systems. Beyond ANSI and ASTM, international codes like ASME reinforce these guidelines. Detailed specifications enable seamless integration in construction projects, from petrochemical plants to waterworks. By following these standards, industries achieve consistent quality, reducing downtime and enhancing safety in flange applications.

Benefits of Using Weld Neck Flanges

Enhanced Pressure Handling Capabilities

Weld neck flanges excel in managing extreme pressures, thanks to their integral neck that distributes stress evenly across the weld joint. In power plants, these flanges support steam lines operating at thousands of psi, preventing deformation or rupture during peak loads. The tapered hub design reinforces the connection, allowing weld neck flanges to handle cyclic pressures without fatigue cracks. Engineers choose weld neck pipe flanges for high-pressure applications in oil and gas pipelines, where they outperform threaded or lap joint alternatives. This capability stems from the full-penetration butt weld, which creates a monolithic structure akin to a continuous pipe. In petrochemical processing, weld neck flanges maintain integrity under pulsating flows from pumps and compressors. Manufacturing facilities benefit from their ability to sustain pressures in hydraulic systems tied to heavy presses. Specifications like ANSI Class 900 ensure weld neck flanges withstand specified pressures at elevated temperatures. Compared to socket weld flanges, necked flanges provide better access for welding, minimizing defects that could compromise pressure ratings. Power plant operators report fewer incidents of pressure-related failures after switching to these robust components. Overall, the enhanced pressure handling of weld neck flanges translates to safer, more efficient operations across engineering disciplines, from heating networks to industrial valves.

Improved Sealing with Flange Gaskets

Flange gaskets pair perfectly with weld neck flanges to create airtight seals, crucial for preventing leaks in pressurized systems. The raised face on many weld neck flanges compresses the gasket material, forming a reliable barrier against fluids and gases. In power plants, engineers select spiral-wound flange gaskets for high-temperature steam applications, where weld neck flanges ensure even bolt loading for optimal compression. This setup reduces the risk of blowouts in boiler feedwater lines. Oil and gas operations use soft gaskets with weld neck stainless steel flanges to seal against corrosive hydrocarbons. The neck design aligns pipes precisely, minimizing gasket misalignment that could lead to failures. In food and beverage lines, FDA-approved gaskets with hygienic weld neck flanges maintain sterility during processing. Waterworks systems employ rubber gaskets for potable water pipes, leveraging the durability of carbon steel weld neck flanges. Proper torquing of bolts enhances sealing performance, as outlined in ASTM guidelines. Petrochemical plants often opt for graphite-filled gaskets to handle aggressive chemicals alongside robust welding neck flanges. This combination extends service life and cuts maintenance costs. Engineers note that improved sealing with flange gaskets in weld neck assemblies boosts overall system efficiency, particularly in valve and nipple connections. Ultimately, these flanges facilitate superior gasket performance, safeguarding operations in diverse industries.

Durability in High-Temperature Environments

Weld neck flanges demonstrate exceptional durability in high-temperature settings, resisting thermal expansion and creep that plague lesser designs. Power plants rely on them in superheater sections, where temperatures exceed 500°C, and the integral neck absorbs differential heating without warping. Stainless steel variants shine in corrosive, hot environments like petrochemical crackers, maintaining structural integrity over decades. Carbon steel weld neck flanges, often alloyed for heat resistance, serve in furnace piping for oil and gas refining. The welding process fuses the flange seamlessly to the pipe, eliminating weak points vulnerable to thermal fatigue. In manufacturing furnaces, these flanges endure repeated heating cycles tied to production demands. Engineering standards from ANSI specify temperature-pressure ratings, guiding selections for specific applications. Heating systems in industrial complexes use weld neck flanges to connect hot water or steam lines, ensuring longevity amid constant exposure. Case in point, power plant retrofits show weld neck flanges outlasting socket types by factors of two or more in turbine exhaust paths. Their tapered profile dissipates heat evenly, reducing localized hot spots. Petrochemical facilities report minimal degradation in distillate lines, thanks to the flanges' robust construction. By prioritizing durability, weld neck flanges minimize unplanned shutdowns, proving indispensable in environments where temperature control defines operational success.

Material Considerations for Weld Neck Flanges

Common Materials: Carbon Steel vs. Stainless Steel

Carbon steel dominates as a common material for weld neck flanges due to its affordability and strength in general applications. Power plants use carbon steel flanges in low-corrosion steam lines, where ASTM A105 grades provide reliable performance. Stainless steel, however, offers superior corrosion resistance, making it the go-to for aggressive environments like petrochemical processing. Grades like 304 or 316 stainless steel weld neck flanges resist pitting from chlorides in oil and gas wells. Carbon steel suits waterworks and basic manufacturing setups, while stainless steel excels in food and beverage lines requiring sanitation. The choice hinges on exposure: carbon steel handles moderate temperatures up to 400°C, but stainless steel pushes to 800°C without oxidizing. Welding neck flanges in carbon steel weld easily with standard electrodes, but stainless variants demand precise techniques to avoid carbide precipitation. Engineering teams weigh these properties during design phases for power plant piping. In construction, carbon steel reduces upfront costs for large-scale projects, whereas stainless steel ensures compliance in regulated sectors. Both materials conform to ANSI dimensions, but stainless steel's higher yield strength supports thinner walls in high-pressure zones. Ultimately, selecting between carbon steel and stainless steel weld neck flanges balances environmental demands with practical needs in pipe and valve assemblies.

Impact of Material Choice on Cost and Performance

Material selection profoundly affects both cost and performance of weld neck flanges, influencing long-term project economics. Carbon steel flanges keep initial costs low, ideal for budget-conscious power plant expansions where corrosion risks remain minimal. Stainless steel, though pricier—often double the cost—delivers unmatched performance in corrosive oil and gas environments, slashing replacement expenses over time. Performance metrics show stainless steel weld neck flanges enduring 50% longer in acidic petrochemical streams, per ASTM tests. Cost analyses reveal that while carbon steel suits waterworks with neutral pH, stainless steel prevents failures in food and beverage acidic processing, avoiding downtime penalties. Engineering calculations factor in lifecycle costs: stainless steel's higher upfront investment yields savings through reduced maintenance in high-temperature heating systems. In manufacturing, carbon steel flanges support heavy loads economically, but stainless variants enhance safety in explosive atmospheres. ANSI standards mandate material traceability, ensuring performance aligns with specs. Power plant operators note that opting for stainless steel in coastal sites cuts corrosion-related repairs by 30%. The trade-off extends to welding: stainless requires specialized fillers, inflating labor costs. Yet, its superior fatigue resistance boosts overall system reliability. By evaluating these impacts, engineers optimize weld neck flange choices for peak performance without excessive expenditure.

Suitability for Various Industries (Oil and Gas, Food and Beverage, Waterworks)

Weld neck flanges adapt seamlessly to diverse industries, with material tweaks enhancing suitability for specific challenges. In the oil and gas industry, high-strength carbon or alloy steel weld neck flanges withstand sour gas corrosion in upstream drilling. Food and beverage operations favor electropolished stainless steel weld neck flanges for sanitary pipe connections, ensuring no metal leaching into products. Waterworks leverage durable carbon steel flanges in buried pipelines, resisting soil pressures and occasional chemicals. Petrochemical plants deploy nickel-alloyed variants for extreme conditions in ethylene production. Manufacturing sectors use them for robust valve and hose integrations under vibration. Power plants integrate weld neck flanges in cooling water systems, where galvanized carbon steel prevents scaling. The oil and gas sector benefits from API-monogrammed flanges meeting stringent pressure specs. In food processing, ASME BPE-compliant stainless flanges maintain hygienic seals with compatible gaskets. Waterworks standards like AWWA emphasize long-term leak-proof performance in municipal infrastructure. Engineering designs tailor neck lengths for flow optimization in each context. Construction projects in these industries standardize on weld neck flanges for their versatility. Stainless steel options shine in the food and beverage realm for clean-in-place systems, while robust carbon steel serves waterworks' volume demands. This adaptability underscores weld neck flanges' role as industry workhorses.

Non-Destructive Testing (NDT) for Weld Neck Flanges

Importance of NDT in Ensuring Quality and Safety

Non-destructive testing (NDT) plays a pivotal role in verifying the quality and safety of weld neck flanges, detecting flaws without compromising the component. In power plants, NDT ensures flanges in critical steam paths remain free of cracks that could lead to explosions. This testing preserves material integrity, aligning with ANSI and ASTM mandates for high-stakes engineering. Safety hinges on identifying subsurface defects from manufacturing or welding, preventing leaks in oil and gas pipelines. NDT provides vital information on weld penetration and material homogeneity, essential for petrochemical facilities handling flammables. Cost savings emerge from early detection, averting expensive repairs or shutdowns in waterworks. Food and beverage industries rely on NDT to confirm stainless steel flanges meet hygiene standards without contamination risks. Engineering protocols integrate NDT at multiple stages: forging, welding, and installation. Power plant inspections reveal that routine NDT extends flange lifespan by catching micro-fractures from thermal stress. In construction, NDT certifies weld neck flanges for seismic zones, enhancing structural resilience. The process fosters confidence in pipe, valve, and nipple assemblies. Ultimately, NDT upholds safety across sectors, ensuring weld neck flanges perform reliably under pressure and heat.

Common NDT Techniques Used in Flange Inspection

Engineers employ several NDT techniques to inspect weld neck flanges, each targeting specific defect types for comprehensive evaluation. Ultrasonic testing (UT) sends sound waves through the flange to detect internal voids or laminations, ideal for thick carbon steel weld neck flanges in power plants. Radiographic testing (RT) uses X-rays to image weld zones, revealing porosity in stainless steel variants for oil and gas applications. Magnetic particle testing (MT) highlights surface cracks on ferromagnetic materials like carbon steel, common in waterworks piping. Dye penetrant testing (PT) uncovers fine surface flaws on non-magnetic stainless steel flanges used in food and beverage lines. Visual testing (VT) serves as the first line, often augmented by borescopes for hard-to-reach neck areas. In petrochemical settings, phased array UT provides detailed mapping of weld neck interfaces. These methods comply with ASTM E709 for MT and E165 for PT, ensuring standardized results. Power plant protocols combine UT and RT for high-pressure flanges, minimizing false positives. NDT teams calibrate equipment for various flange sizes, from small NPT fittings to large pipe flanges. Integration with digital radiography speeds inspections in manufacturing. Collectively, these techniques guarantee defect-free weld neck flanges, bolstering safety in valves and heating systems.

Case Studies: NDT Applications in Power Plants and Petrochemical Facilities

Real-world case studies illustrate NDT's transformative impact on weld neck flanges in demanding settings. At a Midwest power plant, ultrasonic NDT detected subsurface cracks in carbon steel weld neck flanges during a scheduled outage, preventing a potential steam leak that could have halted operations for weeks. Post-repair RT confirmed weld integrity, saving millions in downtime costs. In a Gulf Coast petrochemical facility, magnetic particle testing on stainless steel welding neck flanges exposed fatigue cracks from cyclic loading in a hydrocracker unit. Swift replacement averted a hazardous release of hydrogen sulfide, underscoring NDT's safety value. Another example from an Asian power plant involved dye penetrant inspections on high-temperature flanges, identifying corrosion under insulation that led to enhanced coating protocols. Petrochemical refineries in Europe used phased array UT to assess weld neck pipe flanges in alkylation units, revealing incomplete fusions missed by visual checks. These applications aligned with ANSI B31.3 piping codes, ensuring compliance. In one oil and gas-linked petrochemical site, RT on weld neck stainless steel flanges during construction caught manufacturing defects, avoiding costly field rework. Power plant case studies show NDT reducing failure rates by 40% in boiler feed systems. Such successes highlight how NDT integrates into maintenance strategies, extending flange life in high-stakes environments like valves and pressure vessels.

Installation and Maintenance Best Practices

Proper Welding Techniques for Weld Neck Flanges

Skilled welders apply proper techniques to install weld neck flanges, ensuring a fusion that matches the pipe's strength. Power plant crews use GTAW (TIG) for root passes on stainless steel weld neck flanges, achieving clean, oxide-free joints in high-purity systems. For carbon steel variants in oil and gas lines, SMAW provides efficient multi-pass welding, following ASME Section IX qualifications. Preheating prevents cracking in thick necks, particularly in petrochemical applications. Alignment tools position the tapered hub precisely, minimizing distortion during cooling. Post-weld heat treatment relieves stresses in high-alloy flanges used in heating pipes. Engineers specify backing rings for open-root welds on waterworks flanges to control penetration. In food and beverage setups, orbital welding ensures sanitary seams on stainless steel weld neck flanges. Common pitfalls like undercut avoid through controlled amperage and travel speed. Manufacturing guidelines from ASTM recommend dye penetrant checks post-weld. Power plant installations often involve X-ray verification for critical joints. These techniques extend to valve and nipple connections, fostering leak-proof assemblies. By mastering welding neck flange methods, teams achieve durable installations that withstand operational rigors across industries.

Choosing the Right Flange Gasket and Valve Compatibility

Selecting the appropriate flange gasket and ensuring valve compatibility optimizes weld neck flange performance in piping networks. For power plants, metallic gaskets suit high-pressure weld neck flanges in steam services, compressing reliably under bolt loads. In oil and gas, non-asbestos fiber gaskets pair with carbon steel flanges to seal against hydrocarbons without swelling. Valve compatibility demands matching ANSI classes; a Class 300 weld neck flange aligns seamlessly with gate valves in petrochemical flows. Stainless steel flanges in food and beverage require EPDM gaskets for chemical resistance and easy cleaning. Engineers assess temperature ratings—PTFE gaskets for waterworks handle up to 260°C without degrading. Compatibility extends to face finishes: flat-faced valves need soft gaskets to avoid damage on raised-face weld neck flanges. Cost considerations favor reusable graphite gaskets in manufacturing for repeated installations. In heating systems, spiral-wound gaskets with inner rings prevent intrusion in high-vibration zones. Proper selection prevents leaks at pipe-to-valve transitions. Petrochemical specs often mandate API 6A gaskets for sour service flanges. By prioritizing these factors, installations achieve robust, efficient connections that enhance system longevity and safety.

Routine Inspection and Maintenance for Longevity

Routine inspections and maintenance practices extend the service life of weld neck flanges, keeping systems operational in demanding conditions. Power plant technicians conduct visual checks quarterly, looking for corrosion on carbon steel necks exposed to steam. Ultrasonic thickness gauging monitors wall loss in oil and gas flanges, scheduling coatings when below 90% original thickness. Torque audits ensure bolt integrity on gasketed joints, preventing loosening in vibratory petrochemical environments. Food and beverage lines receive CIP-compatible cleanings to avoid buildup on stainless steel weld neck flanges. Waterworks protocols include hydrostatic testing every five years per AWWA standards. Maintenance logs track NDT results, flagging trends like creep in high-temperature heating applications. Lubricating studs reduces galling during reassembly in manufacturing setups. Engineering teams replace gaskets proactively in valve-flange interfaces to preempt leaks. In construction follow-ups, thermal imaging detects hot spots indicating poor welds. Petrochemical facilities integrate drone inspections for elevated piping. These practices, aligned with ANSI maintenance codes, cut failure risks by half. By committing to routine care, operators maximize weld neck flange longevity, ensuring reliable performance across pipes, hoses, and nipples.

See Also

- The Evolution of Weld Neck Flanges in the Oil and Gas Industry

- Cost Considerations When Selecting Weld Neck Flanges for Your Project

- A Comprehensive Look at the Specifications of Weld Neck Flanges

- Innovative Welding Techniques for Durable Weld Neck Flanges in Industrial Applications

- Understanding the Pressure Ratings of Weld Neck Flanges in Construction